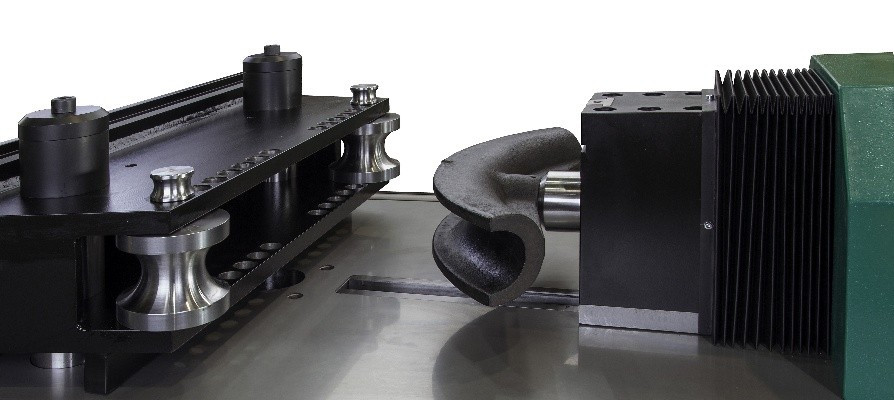

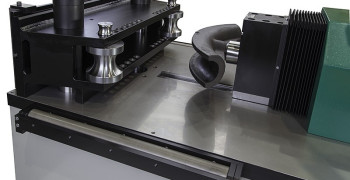

ECO 120

STRAIGHTENING AND BENDING MACHINE FOR BEGINNERS

Technical Data

| Compressive force | 1,200 kN (120 t) |

| Adjustable | 0-1.200 kN |

| Cylinder stroke | 300 mm |

| Clearance | 400-600 mm |

| Motor power | 7,5 kW |

| Operational pressure | 315 bar |

| Bending capacity | 300 x 40 mm at V 240 |

| Straightening capacity | 1,200 with distance of 1,500mm to the straightening block |

| Tool height | 350 mm |

| Dimensions (LxWxH) | 2,400 mm x 950 mm x 1,400 mm |

| Weight | 3.200 kg |

matching products

mod1

Downloads